Plastic Injection

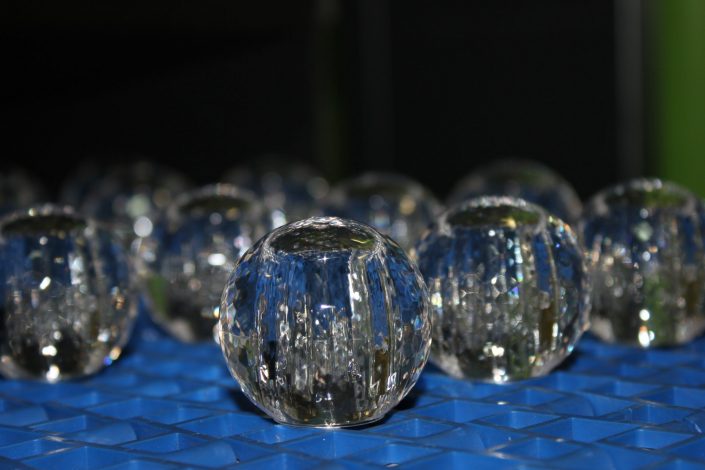

Motecsa manufactures all types of parts through plastic injection procedure in diverse materials, from the most usual to the most technical materials, in order to adapt them to the exigencies of our clients.

In addition, we adapt the color or colors to the material needed in order to manufacture the chosen item.

Our injection machines are prepared to all kinds of thermoplastic (POM, PA, PP, PE, PS, PC, ABS, PBT, SURLYN, etc …).

We have a wide range of automated machinery from 50 tn up to 300 tn.

We develop packaging with different shapes and sizes: from small components to larger packaging with a weight range of 3 g to 800 g.

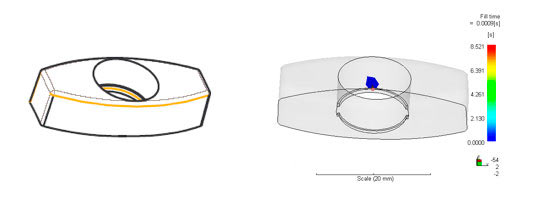

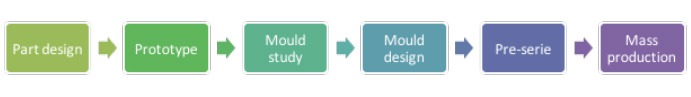

Motecsa performs the parts both from the customer’s molds, and from molds designed by its own technical team.

We have a clean room, specially designed to obtain low levels of contamination.

An internal mold workshop allows us to adapt quickly to the productive needs of our customers.